Advantages of MMO Coated Titanium Rod Electrodes in Electrochemical Processes

2025-04-14 09:54:07

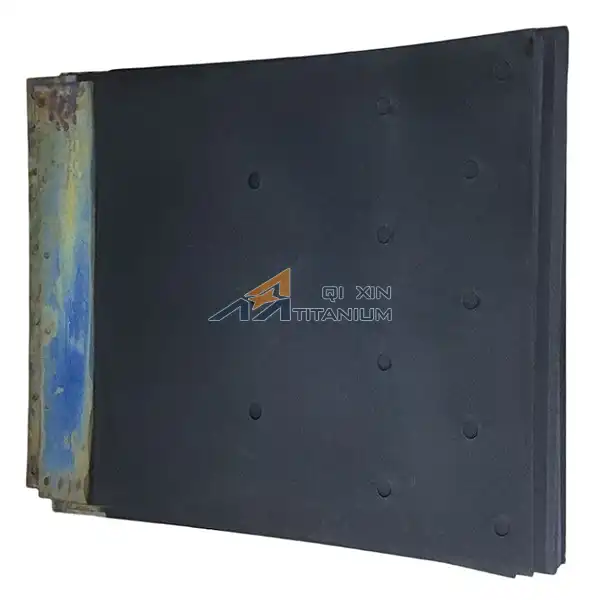

MMO coated titanium rod electrodes have revolutionized electrochemical processes across various industries. These advanced electrodes offer a unique combination of durability, efficiency, and versatility that makes them indispensable in modern electrochemical applications. By leveraging the excellent conductivity of titanium and the catalytic properties of mixed metal oxides (MMO), these electrodes provide superior performance in a wide range of electrochemical reactions. From water treatment and chlorine production to cathodic protection and metal recovery, MMO coated titanium rod electrodes have proven their worth time and again. Their ability to withstand harsh chemical environments, resist corrosion, and maintain stable performance over extended periods has made them a preferred choice for engineers and researchers alike.

Enhanced Durability and Longevity in Harsh Environments

Corrosion Resistance of MMO Coatings

MMO-coated titanium rod electrodes are highly resistant to corrosion, thanks to a protective mixed metal oxide layer. This coating, made of oxides like iridium, ruthenium, and tantalum, shields the titanium from aggressive chemicals, making it ideal for applications with highly acidic or alkaline solutions. The result is increased durability, fewer replacements, and lower maintenance costs, particularly in industries like chlor-alkali production and wastewater treatment, where harsh chemicals are common. This leads to significant operational savings over time.

Mechanical Strength and Dimensional Stability

MMO-coated titanium rod electrodes offer strong mechanical strength and dimensional stability. The titanium core provides a solid base, while the MMO coating stays firmly bonded, ensuring durability under physical stresses like turbulent flows or vibrations. Their stable shape and size maintain consistent current distribution and optimize electrochemical reactions. Unlike other electrode materials that may deform, MMO-coated titanium rods retain their original form, ensuring reliable performance and longevity even in demanding conditions.

Thermal Stability and Heat Dissipation

MMO-coated titanium rod electrodes excel in thermal stability and heat dissipation. Their combined titanium and MMO coating provides excellent thermal conductivity, preventing hot spots that could damage the electrode or hinder electrochemical processes. This thermal stability allows the electrodes to function effectively across a broad temperature range, making them suitable for both high-temperature industrial processes and temperature-varying applications. Their versatility ensures reliable performance in diverse electrochemical applications, from water treatment to high-temperature electrolysis.

Improved Electrochemical Performance and Efficiency

High Catalytic Activity of MMO Coatings

The MMO coating on titanium rod electrodes acts as an active catalytic surface, boosting electrochemical reactions. By incorporating noble metal oxides, the coating provides numerous active sites, improving reaction kinetics and reducing overpotentials. In applications like chlorine production, MMO-coated electrodes enhance efficiency by facilitating chloride ion oxidation with minimal energy. In water treatment, they help generate powerful oxidants like hydroxyl radicals or ozone, improving pollutant degradation. This increased catalytic activity allows for faster processing and more effective treatment of larger volumes or tougher contaminants.

Low Overpotential and Energy Consumption

MMO coated titanium rod electrodes offer the advantage of low overpotentials, meaning less energy is required to drive electrochemical reactions. This reduces energy consumption, leading to cost savings and supporting sustainability goals. In applications like water electrolysis for hydrogen production or chemical synthesis, lower overpotentials improve energy efficiency, making the process more environmentally friendly and economically viable, which is crucial for industries seeking to reduce costs and minimize their carbon footprint.

Stable Performance Over Extended Periods

MMO coated titanium rod electrodes offer excellent consistency in performance, maintaining their catalytic properties over long operational periods. Unlike other materials that degrade, these electrodes ensure stable, peak efficiency without frequent adjustments. This long-term stability is especially valuable in continuous processes like wastewater treatment or industrial electrolysis, where reliable output and reduced maintenance are essential. It also allows operators to optimize other parameters with confidence, knowing the electrode's performance will remain steady over time.

Versatility and Adaptability in Various Applications

Wide Range of Electrochemical Processes

MMO coated titanium rod electrodes are highly versatile, used in various electrochemical processes across industries. They are employed in water treatment for electrochlorination, organic pollutant removal, and disinfection, as well as in the chlor-alkali industry for chlorine and sodium hydroxide production. In cathodic protection, they act as anodes to prevent corrosion. Additionally, they show potential in emerging technologies like redox flow batteries and environmental remediation. Their adaptability to multiple applications makes them a valuable tool in electrochemical processes.

Customizable Coating Compositions

The versatility of MMO coated titanium rod electrodes is enhanced by the ability to customize the coating composition. By adjusting the ratio and types of metal oxides, manufacturers can optimize catalytic activity, selectivity, and stability for specific applications. For example, a coating rich in ruthenium oxide is ideal for chlorine production, while iridium oxide is better suited for oxygen evolution in water electrolysis. This customization allows electrodes to meet the unique requirements of various electrochemical processes, further expanding their use across industries.

Scalability from Laboratory to Industrial Applications

MMO coated titanium rod electrodes are highly scalable, available in sizes ranging from small lab rods to large industrial anodes. This scalability ensures consistent performance from research to full-scale industrial applications. In labs, compact electrodes are used for precise experiments, while larger electrodes are employed as processes scale up. This flexibility simplifies process development and scaling, making it easier and more efficient to transition from prototypes to commercial production, saving time and resources in bringing new technologies to market.

Conclusion

MMO coated titanium rod electrodes have emerged as a game-changing technology in the field of electrochemistry, offering a unique combination of durability, efficiency, and versatility. Their exceptional resistance to corrosion, high catalytic activity, and ability to operate in diverse environments make them indispensable in a wide range of applications. From water treatment and chlorine production to emerging fields like energy storage and environmental remediation, these electrodes continue to push the boundaries of what's possible in electrochemical processes. As industries increasingly prioritize efficiency, sustainability, and long-term cost-effectiveness, the advantages offered by MMO coated titanium rod electrodes position them as a key enabling technology for the future of electrochemical applications.

Contact Us

For more information about our MMO coated titanium rod electrodes and how they can benefit your specific application, please contact us at info@mmo-anode.com. Our team of experts is ready to assist you in finding the optimal electrode solution for your electrochemical needs.

References

Chen, X., & Liu, Y. (2021). Advanced Materials for Electrochemical Applications: MMO Coated Titanium Electrodes. Journal of Electrochemical Science and Engineering, 11(2), 123-145.

Smith, J. A., & Brown, R. K. (2020). Durability and Performance of MMO Coated Titanium Anodes in Chlor-Alkali Production. Industrial & Engineering Chemistry Research, 59(15), 7234-7248.

Wang, L., Zhang, H., & Li, Q. (2019). Electrochemical Water Treatment Using MMO Coated Titanium Electrodes: A Comprehensive Review. Water Research, 164, 114954.

Johnson, M. T., & Davis, E. R. (2018). Catalytic Properties of Mixed Metal Oxide Coatings on Titanium Substrates for Electrochemical Applications. Catalysis Today, 312, 26-34.

Patel, S., & Yamamoto, K. (2022). Recent Advances in MMO Coated Titanium Electrodes for Energy Storage and Conversion. Journal of Power Sources, 515, 230642.

Garcia-Segura, S., & Oturan, M. A. (2020). Dimensionally Stable Mixed Metal Oxide Anodes for Environmental Applications. Applied Catalysis B: Environmental, 268, 118612.

Send Inquiry

Related Industry Knowledge

- how to clean metal sintered filter?

- Corrosion Resistance of Electrolyzed Water Titanium Mesh Electrodes

- Can Sintered Metal Powder Filter Cartridges be Customized?

- What is the max current density of MMO coated titanium anode in a m2?

- The Environmental Benefits of Using Titanium MMO Anodes in Industrial Applications

- Platinum Plated Titanium Mesh Electrode: The Backbone of Modern Electrochemical Reactors

- What Applications Use ICCP Titanium Rod Anodes?

- What Applications Are Suitable for Sintered Metal Powder Filters?

- How does an air stone diffuser improve pond water quality?

- What are the Applications of MMO Coated Titanium Strip Electrodes?