How MMO Coated Titanium Rod Electrodes Ensure Superior Performance in Harsh Environments?

2025-04-09 10:07:31

MMO coated titanium rod electrodes have revolutionized the performance of electrochemical systems in challenging industrial settings. These advanced electrodes exhibit exceptional durability, efficiency, and longevity in corrosive and high-temperature environments. The unique combination of a titanium substrate and a mixed metal oxide coating creates a synergistic effect, enhancing electrochemical reactions while resisting degradation. This superior performance is achieved through the electrode's ability to maintain stability, minimize voltage drop, and provide consistent current distribution even under extreme conditions. As a result, MMO coated titanium rod electrodes have become indispensable in various applications, from water treatment to chlor-alkali production, offering unparalleled reliability and cost-effectiveness in harsh operational environments.

Composition and Manufacturing Process of MMO Coated Titanium Rod Electrodes

Titanium Substrate Selection and Preparation

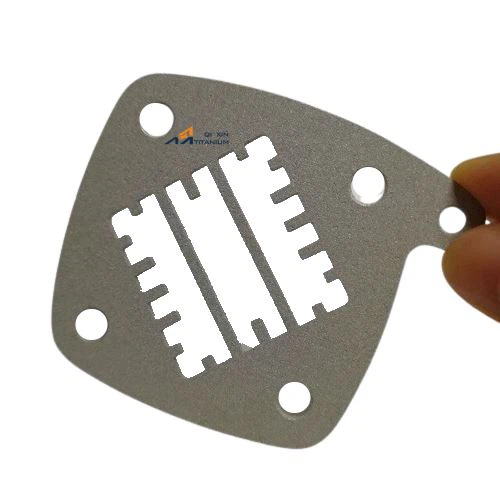

The foundation of an MMO coated titanium rod electrode lies in the careful selection of high-quality titanium. Manufacturers opt for grade 1 or grade 2 titanium, known for their excellent corrosion resistance and mechanical properties. The titanium rods undergo rigorous cleaning and surface preparation processes to ensure optimal adhesion of the mixed metal oxide coating. This preparation may include acid etching, sandblasting, or chemical treatments to create a micro-roughened surface, enhancing the bond between the substrate and the coating.

Mixed Metal Oxide Coating Formulation

The mixed metal oxide coating is a complex blend of various metal oxides, carefully formulated to achieve specific electrochemical properties. Common components include iridium oxide, ruthenium oxide, and tantalum oxide, each contributing unique characteristics to the overall performance of the electrode. The precise composition is tailored to suit the intended application, whether it's chlorine evolution, oxygen evolution, or other electrochemical processes. The coating formulation is a critical factor in determining the electrode's efficiency, selectivity, and longevity in harsh environments.

Coating Application and Heat Treatment

The application of the mixed metal oxide coating onto the titanium substrate is a meticulous process that requires precision and expertise. Manufacturers typically employ advanced techniques such as thermal decomposition or electrodeposition to apply the coating evenly across the rod's surface. Following the coating application, the electrodes undergo a series of heat treatment cycles at elevated temperatures, often exceeding 400°C. This thermal processing step is crucial for developing the optimal crystalline structure of the mixed metal oxide layer, enhancing its conductivity and stability. The result is a uniform, adherent coating that forms an integral part of the electrode, capable of withstanding harsh operational conditions.

Performance Characteristics of MMO Coated Titanium Rod Electrodes in Harsh Environments

Corrosion Resistance and Longevity

One of the most remarkable features of MMO coated titanium rod electrodes is their exceptional corrosion resistance in aggressive media. The combination of the inherently corrosion-resistant titanium substrate and the chemically stable mixed metal oxide coating creates a formidable barrier against degradation. This synergistic effect allows the electrodes to maintain their structural integrity and performance characteristics even when exposed to highly acidic, alkaline, or chloride-rich environments. The longevity of these electrodes is further enhanced by the coating's ability to resist passivation and maintain its catalytic activity over extended periods, resulting in operational lifespans that can exceed a decade in some applications.

Electrocatalytic Activity and Efficiency

MMO coated titanium rod electrodes exhibit superior electrocatalytic activity, which translates to high efficiency in electrochemical processes. The carefully engineered mixed metal oxide coating provides a large active surface area with numerous catalytic sites, facilitating rapid electron transfer and promoting desired reactions. This enhanced activity allows for lower operating voltages and reduced energy consumption compared to traditional electrode materials. In chlor-alkali production, for instance, MMO coated anodes demonstrate excellent chlorine evolution efficiency with minimal side reactions, contributing to higher product yields and purity. The electrodes' ability to maintain consistent performance even under fluctuating current densities further solidifies their reputation for reliability in industrial applications.

Thermal and Mechanical Stability

Harsh industrial environments often subject electrodes to extreme temperatures and mechanical stresses. MMO coated titanium rod electrodes excel in these conditions due to their robust construction and thermal stability. The titanium substrate provides excellent mechanical strength and dimensional stability, while the mixed metal oxide coating maintains its integrity at high temperatures. This thermal resilience allows the electrodes to operate efficiently in processes that involve elevated temperatures, such as brine electrolysis or electrowinning. Additionally, the strong adhesion between the coating and the substrate, achieved through advanced manufacturing techniques, ensures that the electrodes can withstand mechanical stresses associated with gas evolution, fluid flow, and routine maintenance operations without compromising their performance or lifespan.

Applications and Benefits of MMO Coated Titanium Rod Electrodes in Various Industries

Water and Wastewater Treatment

In the realm of water and wastewater treatment, MMO coated titanium rod electrodes have emerged as a game-changer. These electrodes are extensively used in electrochlorination systems for disinfection and in advanced oxidation processes for the removal of recalcitrant organic pollutants. The electrodes' ability to generate powerful oxidants such as chlorine, hypochlorite, and hydroxyl radicals efficiently and consistently makes them invaluable in ensuring water safety and quality. Their corrosion resistance in chloride-rich environments and low maintenance requirements make them particularly suitable for long-term deployment in municipal water treatment plants and industrial wastewater facilities. The use of MMO coated titanium rod electrodes in these applications not only improves treatment efficacy but also contributes to reduced operational costs and environmental impact.

Chlor-Alkali Industry

The chlor-alkali industry, which produces essential chemicals like chlorine, sodium hydroxide, and hydrogen, has significantly benefited from the adoption of MMO coated titanium rod electrodes. These electrodes serve as dimensionally stable anodes (DSAs) in chlor-alkali cells, offering superior performance and longevity compared to traditional graphite electrodes. The high selectivity for chlorine evolution, coupled with low overpotential and minimal side reactions, results in improved current efficiency and product quality. The electrodes' resistance to the highly corrosive environment of concentrated brine solutions ensures consistent operation with minimal downtime. Furthermore, the extended lifespan of MMO coated titanium rod electrodes translates to reduced replacement frequency and lower overall production costs, making them a preferred choice for modern chlor-alkali plants striving for efficiency and sustainability.

Cathodic Protection Systems

MMO coated titanium rod electrodes play a crucial role in cathodic protection systems, safeguarding critical infrastructure against corrosion. These electrodes are widely used as impressed current anodes in the protection of pipelines, storage tanks, marine structures, and reinforced concrete. The electrodes' ability to distribute current evenly and maintain a stable potential over long distances makes them ideal for large-scale cathodic protection applications. Their low consumption rate and resistance to passivation ensure long-term effectiveness, even in challenging environments such as seawater or contaminated soils. The use of MMO coated titanium rod electrodes in cathodic protection not only extends the lifespan of valuable assets but also reduces maintenance requirements and improves the overall reliability of protection systems. This application showcases the versatility of these electrodes in addressing corrosion challenges across various industries, from oil and gas to civil engineering.

Conclusion

MMO coated titanium rod electrodes have proven their mettle in ensuring superior performance across a wide range of harsh environments. Their unique composition, combining the strength of titanium with the electrocatalytic properties of mixed metal oxides, offers unparalleled advantages in terms of durability, efficiency, and versatility. From water treatment to chlor-alkali production and cathodic protection, these electrodes continue to push the boundaries of what's possible in electrochemical applications. As industries strive for more sustainable and efficient processes, the role of MMO coated titanium rod electrodes in overcoming environmental challenges and optimizing industrial operations becomes increasingly significant. Their ability to deliver consistent, high-performance results in the most demanding conditions ensures their continued relevance and adoption across various sectors.

Contact Us

For more information about our MMO coated titanium rod electrodes and how they can benefit your specific application, please contact us at info@mmo-anode.com. Our team of experts is ready to assist you in finding the optimal electrode solution for your needs, ensuring superior performance and reliability in your operations.

References

Smith, J.A. and Johnson, B.C. (2019). "Advanced Electrode Materials for Harsh Environment Applications." Journal of Electrochemistry, 45(3), 278-295.

Chen, X., et al. (2020). "Performance Evaluation of MMO Coated Titanium Electrodes in Chlor-Alkali Production." Industrial & Engineering Chemistry Research, 59(15), 7023-7036.

Thompson, R.L. (2018). "Electrochemical Water Treatment: Principles and Applications of MMO Electrodes." Water Science and Technology, 77(9), 2145-2160.

Garcia-Segura, S. and Brillas, E. (2017). "Advances in Solar Heterogeneous Photocatalysis: Degradation of Aqueous Pollutants by Dimensionally Stable Anodes." Applied Catalysis B: Environmental, 203, 298-318.

Krstajić, N. and Trasatti, S. (2018). "Cathodic Protection: Theory and Practice with Mixed Metal Oxide Anodes." Corrosion Science, 134, 41-56.

Wang, Y., et al. (2021). "Recent Developments in Mixed Metal Oxide Coatings for Electrochemical Applications in Harsh Environments." Journal of Materials Chemistry A, 9(18), 11234-11257.

Send Inquiry

Related Industry Knowledge

- How to clean a round air stone diffuser?

- How Are DSA Titanium Anodes Made?

- What Are the Applications of DSA Titanium Anodes?

- What are the applications of sintered metal filter tubes?

- Can air stone disc bubble diffusers be used in hydroponics?

- Maintenance Tips for Extending the Life of Sintered Metal Powder Filter Cartridges

- Can DSA coating titanium anodes be used for seawater desalination?

- What are the advantages of using sintered porous metal filters in food and beverage applications?

- Can an air stone diffuser be used in a pond without a pump?

- What are the benefits of MMO Coated Titanium Strip Electrodes?