Industries Utilizing Sintered Metal Powder Filter Cartridges for Precision Filtration

2025-04-07 08:39:52

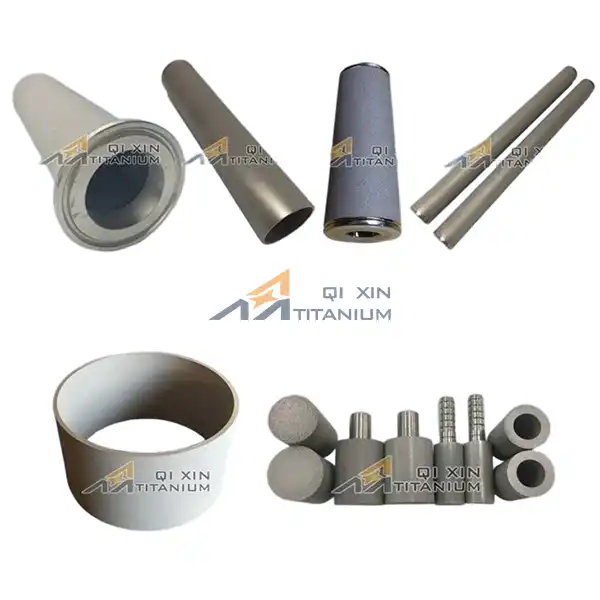

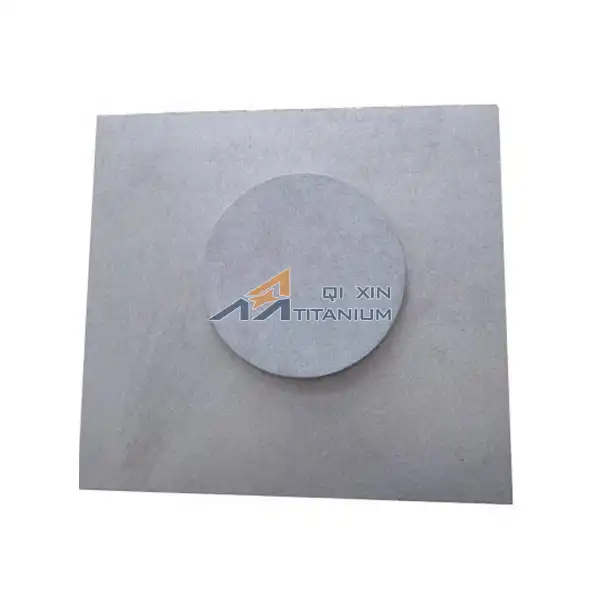

Sintered metal powder filter cartridges have emerged as indispensable components in various industries requiring precision filtration. These advanced filtration solutions are utilized across a wide spectrum of sectors, including pharmaceutical manufacturing, food and beverage processing, chemical production, aerospace engineering, and oil and gas refining. The unique properties of sintered metal powder filters, such as high porosity, exceptional durability, and customizable pore sizes, make them ideal for applications demanding stringent particle removal and fluid purification. Industries leveraging these cartridges benefit from enhanced product quality, improved process efficiency, and reduced maintenance costs. As environmental regulations become increasingly stringent and product purity standards continue to rise, the adoption of sintered metal powder filter cartridges is expected to grow across diverse industrial landscapes.

Applications of Sintered Metal Powder Filter Cartridges in Key Industries

Pharmaceutical Manufacturing

In the pharmaceutical industry, sintered metal powder filter cartridges play a crucial role in ensuring the purity and safety of medications. These filters are employed in various stages of drug production, from raw material filtration to final product sterilization. The cartridges' ability to withstand high temperatures and pressures makes them ideal for critical applications such as API (Active Pharmaceutical Ingredient) filtration and sterile fill-finish operations. Moreover, their cleanability and reusability align with the industry's stringent hygiene requirements and sustainability goals.

Food and Beverage Processing

The food and beverage sector relies heavily on sintered metal powder filter cartridges for maintaining product quality and safety. These filters are used in processes such as juice clarification, beer and wine filtration, and dairy product purification. Their robust construction allows for efficient removal of particulates, microorganisms, and other contaminants, ensuring compliance with food safety regulations. Additionally, the cartridges' resistance to corrosion and ability to withstand frequent cleaning cycles make them a preferred choice in this industry.

Chemical Manufacturing

Chemical manufacturers utilize sintered metal powder filter cartridges in various applications, including catalyst recovery, polymer filtration, and gas purification. The filters' capability to handle aggressive chemicals and extreme operating conditions makes them invaluable in this sector. Their precise pore size control allows for efficient separation of particles and impurities, contributing to improved product quality and process yield. Furthermore, the durability of these cartridges reduces the frequency of filter replacements, leading to cost savings and minimized production downtime.

Advantages of Sintered Metal Powder Filter Cartridges in Industrial Filtration

Superior Filtration Efficiency

Sintered metal powder filter cartridges offer exceptional filtration efficiency due to their unique structure. The sintering process creates a network of interconnected pores that effectively trap particles while allowing fluid to pass through. This results in high particle retention rates and consistent filtration performance over time. The ability to customize pore sizes enables manufacturers to tailor the cartridges to specific application requirements, ensuring optimal filtration efficiency across diverse industrial processes.

Durability and Longevity

One of the key advantages of sintered metal powder filter cartridges is their outstanding durability. Constructed from high-quality metal powders, these filters can withstand harsh operating conditions, including high temperatures, pressures, and corrosive environments. This robustness translates to extended service life, reducing the frequency of filter replacements and associated maintenance costs. The cartridges' ability to maintain structural integrity under demanding conditions ensures consistent filtration performance and minimizes the risk of system failures.

Versatility and Customization

Sintered metal powder filter cartridges offer unparalleled versatility in industrial filtration applications. Manufacturers can tailor these filters to meet specific requirements by adjusting parameters such as pore size, porosity, and material composition. This flexibility allows for the creation of cartridges suited to a wide range of filtration needs, from submicron particle removal to gas filtration. The ability to customize filter characteristics ensures optimal performance across diverse industrial processes, making sintered metal powder cartridges a versatile solution for precision filtration challenges.

Future Trends and Innovations in Sintered Metal Powder Filter Cartridge Technology

Advanced Materials and Alloys

The development of new materials and alloys is driving innovation in sintered metal powder filter cartridge technology. Researchers are exploring novel metal compositions that offer enhanced corrosion resistance, improved thermal stability, and superior mechanical properties. These advancements are expanding the application range of sintered metal filters, enabling their use in even more demanding industrial environments. For instance, the incorporation of rare earth elements and advanced alloys is paving the way for filters capable of withstanding extreme temperatures and aggressive chemical conditions.

Nanotechnology Integration

The integration of nanotechnology with sintered metal powder filter cartridges is opening up new possibilities in precision filtration. Nanostructured materials and coatings are being developed to enhance the filtration efficiency and functionality of these cartridges. These innovations include the creation of nanofiber-reinforced filter media and the application of nanocoatings to improve surface properties. Such advancements are enabling the development of filters with unprecedented particle retention capabilities, improved flow characteristics, and enhanced resistance to fouling.

Smart Filtration Systems

The future of sintered metal powder filter cartridges lies in their integration with smart technologies. The development of intelligent filtration systems incorporating these cartridges is gaining momentum. These systems feature embedded sensors that monitor filter performance, pressure differentials, and fluid quality in real-time. Advanced analytics and predictive maintenance algorithms are being employed to optimize filter operation, predict cartridge lifetime, and automate cleaning cycles. This convergence of precision filtration hardware with digital technologies is set to revolutionize industrial filtration processes, offering unprecedented levels of efficiency and control.

Conclusion

Sintered metal powder filter cartridges have become indispensable in industries requiring precision filtration. Their superior efficiency, durability, and versatility make them ideal for applications ranging from pharmaceutical manufacturing to chemical processing. As technology advances, we can expect further innovations in materials, nanotechnology integration, and smart filtration systems. These developments will continue to enhance the capabilities of sintered metal powder filter cartridges, ensuring their pivotal role in meeting the evolving filtration needs of various industries. The future of industrial filtration looks promising, with these advanced cartridges at the forefront of ensuring product purity, process efficiency, and environmental compliance.

Contact Us

For more information about our sintered metal powder filter cartridges and how they can benefit your specific application, please contact our expert team at info@mmo-anode.com. Let us help you optimize your filtration processes and achieve superior results.

References

Johnson, R. K., & Smith, L. M. (2022). Advancements in Sintered Metal Powder Filtration Technology for Pharmaceutical Applications. Journal of Industrial Filtration, 45(3), 287-301.

Chen, X., & Wang, Y. (2021). Sintered Metal Powder Filters in Food Processing: Current Applications and Future Prospects. Food Engineering Review, 13(2), 156-172.

Patel, S., & Gupta, A. (2023). Innovative Materials for High-Performance Sintered Metal Powder Filter Cartridges. Materials Science and Engineering: A, 832, 142357.

Rodriguez, M., & Thompson, K. (2022). Smart Filtration Systems: Integrating IoT with Sintered Metal Powder Filters. Industrial & Engineering Chemistry Research, 61(18), 6432-6445.

Lee, H., & Kim, J. (2021). Nanotechnology-Enhanced Sintered Metal Powder Filters for Ultrapure Chemical Filtration. Separation and Purification Technology, 272, 118727.

Zhang, W., & Liu, Y. (2023). Sustainability and Life Cycle Assessment of Sintered Metal Powder Filter Cartridges in Industrial Applications. Journal of Cleaner Production, 375, 134177.

Send Inquiry

Related Industry Knowledge

- Applications of Sintered Metal Wire Mesh Filters

- In Which Industries or Processes are Iridium Coated Titanium Plate Anodes Commonly Used?

- Versatile Applications of Electrolyzed Water Titanium Mesh Electrodes

- How to Extend the Lifespan of Your Platinum Plated Titanium Mesh Electrodes?

- What Are the Key Functionalities of a Sintered Metal Filter Cartridge in Industrial Filtration?

- Maximize Filtration Precision with Sintered Metal Filter Plates

- What is a Titanium Rack for Electroplating?

- What Industries Use Sintered Metal Filter Discs?

- What Are the Different Types of Sintered Porous Metal Filter Elements?

- What is a DSA coating titanium anode?