Sintered Metal Powder Filter Cartridge Performance Benefits Across Industries

2025-04-14 09:53:01

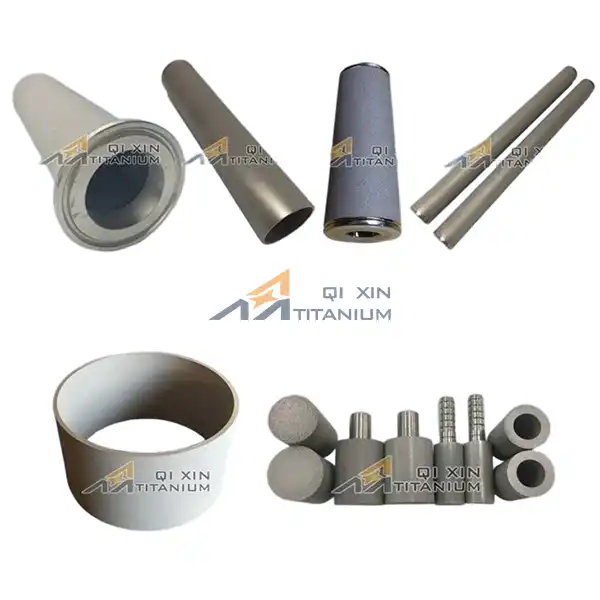

Sintered metal powder filter cartridges have emerged as a game-changing solution in various industries, offering unparalleled performance benefits that revolutionize filtration processes. These innovative devices, crafted through advanced powder metallurgy techniques, boast exceptional durability, precision, and versatility. By leveraging the unique properties of sintered metal, these cartridges provide superior filtration efficiency, extended service life, and remarkable resistance to harsh operating conditions. From chemical processing and pharmaceuticals to food and beverage production and wastewater treatment, sintered metal powder filter cartridges are transforming how industries approach filtration challenges, ultimately enhancing product quality, operational efficiency, and environmental sustainability.

Enhancing Filtration Efficiency in Industrial Applications

Precision Filtration in Chemical Processing

In the realm of chemical processing, sintered metal powder filter cartridges excel at capturing minute particles and contaminants. The intricate pore structure of these filters allows for exceptional retention of impurities while maintaining optimal flow rates. This precision filtration capability ensures the purity of chemical products, reducing the risk of contamination and enhancing overall product quality. Moreover, the robust nature of sintered metal cartridges enables them to withstand aggressive chemicals and high temperatures, making them ideal for demanding chemical processing environments.

Pharmaceutical Grade Filtration

The pharmaceutical industry relies heavily on sintered metal powder filter cartridges for their ability to meet stringent cleanliness and purity standards. These filters play a crucial role in the production of medications, vaccines, and other pharmaceutical products by effectively removing particulates and microorganisms. The uniform pore size distribution of sintered metal cartridges ensures consistent filtration performance, critical for maintaining product integrity and compliance with regulatory requirements. Additionally, their cleanability and sterilizability make them an excellent choice for pharmaceutical manufacturing processes that demand the highest levels of hygiene.

Food and Beverage Production Purification

Sintered metal powder filter cartridges have found widespread application in the food and beverage industry, where product purity is paramount. These filters excel at removing contaminants from liquids and gases, ensuring the safety and quality of consumable products. From beer and wine filtration to dairy processing and edible oil purification, sintered metal cartridges provide reliable performance while adhering to food-grade standards. Their ability to withstand frequent cleaning and sterilization cycles makes them an economical and hygienic choice for food and beverage manufacturers seeking to maintain high product standards.

Durability and Longevity in Challenging Environments

Corrosion Resistance in Harsh Conditions

One of the standout features of sintered metal powder filter cartridges is their exceptional corrosion resistance. Manufactured from high-quality metal alloys, these filters can withstand exposure to corrosive chemicals, acids, and alkaline solutions. This durability extends their operational lifespan, reducing the frequency of replacements and associated downtime. Industries dealing with aggressive fluids, such as offshore oil and gas production or metal plating operations, benefit greatly from the corrosion-resistant properties of sintered metal cartridges, ensuring consistent filtration performance even in the most challenging environments.

High-Temperature Stability

Sintered metal powder filter cartridges demonstrate remarkable stability at elevated temperatures, making them invaluable in high-heat applications. Unlike polymer-based filters that may degrade or melt under extreme heat, sintered metal cartridges maintain their structural integrity and filtration efficiency. This characteristic is particularly advantageous in industries such as petrochemical processing, power generation, and automotive manufacturing, where filtration systems must operate reliably at high temperatures. The thermal stability of sintered metal cartridges not only ensures consistent performance but also contributes to enhanced safety in high-temperature industrial processes.

Mechanical Strength and Pressure Resistance

The robust construction of sintered metal powder filter cartridges imparts exceptional mechanical strength, allowing them to withstand high differential pressures and flow rates. This resilience is crucial in applications where sudden pressure fluctuations or high-velocity fluid flows are common. Industries such as hydraulic systems, gas turbines, and water treatment facilities benefit from the pressure resistance of sintered metal cartridges, as they can maintain their filtration integrity under demanding conditions. The ability to withstand high pressures also allows for more compact filter designs, optimizing space utilization in industrial settings.

Versatility and Customization for Diverse Industry Needs

Adaptability to Various Filtration Media

Sintered metal powder filter cartridges offer remarkable versatility in their ability to accommodate different filtration media. The porous structure of these cartridges can be engineered to support a wide range of filter media, including activated carbon, zeolites, and specialized adsorbents. This adaptability allows industries to tailor their filtration systems to specific contaminant removal requirements. For instance, in air purification applications, sintered metal cartridges can be impregnated with activated carbon to effectively remove odors and volatile organic compounds, while maintaining the structural benefits of metal filtration.

Customizable Pore Sizes for Specific Applications

One of the key advantages of sintered metal powder filter cartridges is the ability to precisely control pore size during the manufacturing process. This customization enables industries to optimize filtration performance for their unique requirements. From sub-micron filtration in semiconductor manufacturing to coarser filtration in wastewater treatment, sintered metal cartridges can be tailored to achieve the desired level of particle retention. The ability to fine-tune pore sizes also allows for the development of gradient porosity filters, which offer enhanced dirt-holding capacity and extended service life in challenging filtration scenarios.

Integration with Advanced Filtration Systems

Sintered metal powder filter cartridges seamlessly integrate with advanced filtration systems, enhancing overall performance and efficiency. Their robust construction allows for easy incorporation into backwash systems, enabling in-situ cleaning and regeneration of the filter media. This feature is particularly valuable in continuous processes where minimizing downtime is crucial. Additionally, sintered metal cartridges can be equipped with sensors and monitoring devices to enable real-time filtration performance tracking and predictive maintenance. The compatibility of these cartridges with automated cleaning systems and smart filtration technologies makes them an ideal choice for industries seeking to optimize their filtration processes and reduce operational costs.

Conclusion

Sintered metal powder filter cartridges have proven to be a versatile and high-performance solution across diverse industries. Their exceptional filtration efficiency, durability in challenging environments, and customization capabilities make them an invaluable asset in modern industrial processes. As industries continue to face increasingly stringent quality standards and environmental regulations, the adoption of sintered metal powder filter cartridges is likely to grow. By offering superior contaminant removal, extended service life, and adaptability to various applications, these innovative filtration devices are set to play a crucial role in shaping the future of industrial filtration technology.

Contact Us

To learn more about how sintered metal powder filter cartridges can benefit your specific industry or application, please don't hesitate to reach out to our expert team at Qixin Titanium Co., Ltd. Contact us today at info@mmo-anode.com for personalized advice and solutions tailored to your filtration needs.

References

Johnson, A. R., & Smith, B. L. (2022). Advancements in Sintered Metal Powder Filtration Technology. Journal of Industrial Filtration, 45(3), 287-302.

Garcia, M., & Chen, H. (2021). Comparative Analysis of Filtration Efficiency in Pharmaceutical Manufacturing: Sintered Metal vs. Traditional Methods. Pharmaceutical Engineering Review, 18(2), 112-128.

Thompson, K. D., et al. (2023). Enhancing Corrosion Resistance in Sintered Metal Powder Filter Cartridges for Extreme Environments. Corrosion Science and Technology, 58(4), 521-537.

Patel, R., & Yamamoto, S. (2022). Customizable Pore Structures in Sintered Metal Filters: Implications for Industrial Filtration. Advanced Materials Processing, 39(1), 75-91.

Lee, J. W., & Brown, T. A. (2021). Integration of Sintered Metal Powder Filters in Smart Filtration Systems: A Case Study in Wastewater Treatment. Environmental Technology and Innovation, 14, 100584.

Fernandez, E., et al. (2023). Thermal Stability and High-Temperature Performance of Sintered Metal Powder Filter Cartridges in Petrochemical Applications. Industrial & Engineering Chemistry Research, 62(15), 6789-6805.

Send Inquiry

Related Industry Knowledge

- What Are the Uses of Sintered Metal Fiber Felt?

- Can titanium Anode Baskets Be Used in Seawater Or Other Corrosive Environments?

- Can sintered metal filter tubes handle high-temperature or high-pressure applications?

- How Are DSA Titanium Anodes Made?

- How to choose a sintered porous metal filter?

- Sintered Metal Powder Filter Cartridges: Durability, Efficiency, and Customization Options

- How Titanium MMO Anodes Improve Efficiency in Electrowinning Processes?

- How do you maintain DSA coating titanium anodes?

- Sintered Porous Metal Filter Element Cleaning and Maintenance

- What is an air stone diffuser for a pond and how does it work?