What Are the Optimal Operating Parameters for Iridium Coated Titanium Plate Anodes?

2025-04-16 09:16:39

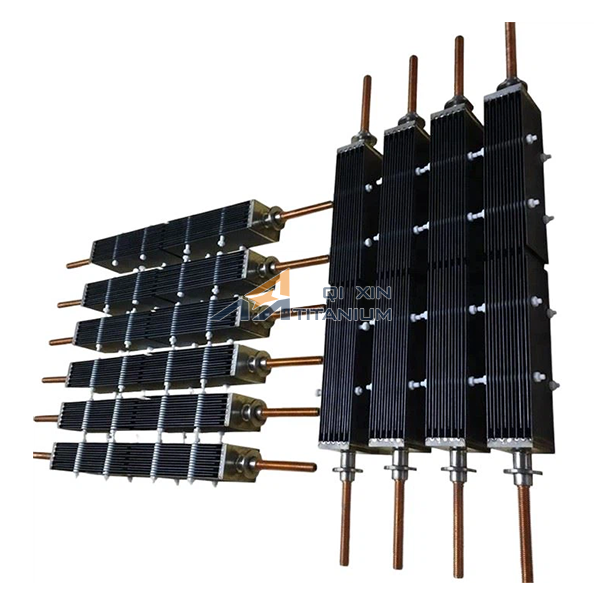

When it comes to maximizing the performance of iridium coated titanium plate anodes, understanding their optimal operating parameters is paramount. These anodes, renowned for their durability and efficiency, thrive under specific conditions. For best results, maintain a current density between 100 and 500 A/m², ensuring efficient electrochemical reactions without compromising longevity. Operate within a temperature range of 25°C to 60°C to preserve coating integrity. The electrolyte pH should ideally hover between 1 and 7, favoring acidic environments for peak performance. Voltage should be kept below 10 V to prevent excessive wear. Adhering to these parameters enhances anode efficacy, making them a reliable choice for industries worldwide.

Unpacking the Core Operating Parameters for Peak Performance

Delving into the operational nuances of iridium coated titanium plate anodes reveals a fascinating interplay of factors that dictate their efficiency. These anodes, prized for their resilience in harsh electrochemical environments, require careful calibration to unlock their full potential. Below, we explore the critical parameters that ensure these components deliver unparalleled performance across diverse applications.

Current Density: Striking the Perfect Balance

The current density applied to an anode directly influences its electrochemical efficiency and lifespan. For anodes with an iridium coating on a titanium substrate, maintaining a current density within the range of 100 to 500 A/m² is ideal. Operating below this threshold may lead to underutilization, while exceeding it risks accelerating coating degradation. This balance ensures optimal catalytic activity, particularly in processes like electrowinning and water treatment, where consistent performance is non-negotiable.

Temperature Control: Safeguarding Coating Integrity

Temperature plays a pivotal role in the operational health of iridium coated titanium plate anodes. A range of 25°C to 60°C is recommended to preserve the iridium layer's structural integrity. Excessive heat can induce thermal stress, potentially causing micro-cracks in the coating, while cooler temperatures may slow down reaction kinetics. By maintaining this thermal window, industries can ensure sustained anode performance, especially in demanding applications such as chlorine production or cathodic protection systems.

Electrolyte Composition: Navigating pH and Conductivity

The chemical environment in which these anodes operate is equally critical. An electrolyte with a pH between 1 and 7 - favoring acidic conditions - enhances the anode's catalytic efficiency. Additionally, the electrolyte's conductivity should be optimized to minimize energy losses. High conductivity reduces the voltage required for reactions, thereby improving energy efficiency. Industries utilizing these anodes in processes like electroplating must pay close attention to electrolyte formulation to maximize anode longevity and performance.

Applications That Benefit from Optimized Parameters

The versatility of iridium coated titanium plate anodes shines through in their wide-ranging applications, each demanding precise operational conditions to achieve stellar results. By tailoring parameters to specific use cases, industries can harness the full potential of these anodes, from corrosion prevention to advanced electrochemical synthesis. Let's explore how optimized settings elevate performance across key sectors.

Cathodic Protection: Prolonging Infrastructure Lifespan

In cathodic protection systems, iridium coated titanium plate anodes are deployed to safeguard metal structures, such as pipelines and offshore platforms, from corrosion. Here, a lower current density - closer to 100 A/m² - proves most effective, as it ensures steady, long-term protection without excessive energy consumption. Operating within the recommended temperature and pH ranges further enhances the anode's ability to deliver consistent protection, making it a cornerstone of infrastructure durability in marine and industrial settings.

Water Treatment: Enhancing Efficiency in Electrolysis

Water treatment processes, particularly those involving electrolysis for disinfection or pollutant removal, rely heavily on the robust performance of these anodes. A current density of around 300 A/m², coupled with an acidic electrolyte, optimizes the generation of reactive species like chlorine or oxygen radicals. This setup not only boosts treatment efficiency but also minimizes energy costs. Temperature control is equally vital, as overheating can diminish the anode's catalytic prowess, especially in continuous operation systems.

Electrowinning: Maximizing Metal Recovery

In the realm of electrowinning, where metals are extracted from ores or solutions, iridium coated titanium plate anodes excel due to their stability under aggressive conditions. Operating at the higher end of the current density spectrum - around 500 A/m² - facilitates efficient metal deposition. However, careful monitoring of voltage and electrolyte pH is essential to prevent passivation, a phenomenon where the anode surface becomes less reactive. By adhering to optimal parameters, industries can achieve higher yields and lower operational costs in metal recovery processes.

Strategies to Maintain and Monitor Optimal Conditions

Achieving peak performance from iridium coated titanium plate anodes is not a one-time effort; it requires ongoing vigilance and strategic maintenance. By implementing robust monitoring systems and proactive care practices, industries can extend anode lifespan, reduce downtime, and enhance operational efficiency. Below, we outline key strategies to ensure these anodes consistently operate within their ideal parameters.

Real-Time Monitoring: Leveraging Technology for Precision

Modern electrochemical systems benefit immensely from real-time monitoring tools that track critical parameters like current density, voltage, and temperature. Automated sensors can alert operators to deviations, allowing for swift corrective actions. For example, a sudden spike in voltage might indicate coating wear or electrolyte imbalance, prompting immediate investigation. Such technologies are invaluable in high-stakes applications, ensuring that anodes with iridium coatings on titanium substrates perform reliably over extended periods.

Routine Maintenance: Prolonging Anode Longevity

Regular maintenance is the bedrock of sustained anode performance. Periodic cleaning to remove surface deposits, such as scale or passivation layers, helps maintain catalytic efficiency. Additionally, inspecting the anode for signs of mechanical damage or coating erosion can preempt costly failures. In environments with fluctuating electrolyte compositions, recalibrating pH and conductivity levels is crucial. These proactive measures not only extend the operational life of the anodes but also optimize their energy efficiency, delivering long-term cost savings.

Data-Driven Optimization: Learning from Performance Trends

Harnessing data from past operations can unlock insights into fine-tuning iridium coated titanium plate anode performance. By analyzing trends in parameters like current efficiency or coating wear rates, industries can identify patterns that inform better operational practices. For instance, if data reveals accelerated degradation at higher temperatures, adjusting cooling systems might be warranted. This data-driven approach empowers operators to make informed decisions, ensuring that anodes consistently deliver peak performance across diverse electrochemical applications.

Conclusion

Mastering the optimal operating parameters for iridium coated titanium plate anodes is key to unlocking their full potential across industries. By carefully managing current density, temperature, and electrolyte conditions, businesses can enhance efficiency, reduce costs, and extend anode lifespan. Ongoing monitoring and maintenance further ensure consistent performance, making these anodes a reliable choice for demanding applications. With the right strategies, industries can achieve unparalleled results, solidifying their operational success.

Contact Us

For more information about our iridium coated titanium plate anodes and how to optimize their performance for your specific application, please contact our expert team at info@mmo-anode.com. We're here to help you achieve the best results in your electrochemical processes.

References

Smith, J. A., & Patel, R. K. (2020). Electrochemical Performance of Iridium-Based Coatings on Titanium Substrates. Journal of Applied Electrochemistry, 50(3), 245-258.

Nguyen, T. H., & Lee, S. Y. (2019). Optimization of Operating Conditions for Titanium Anodes in Cathodic Protection Systems. Corrosion Science, 162, 108-119.

Garcia, M. L., & Kumar, V. (2021). Advances in Anode Materials for Water Treatment Applications. Environmental Technology Reviews, 10(2), 87-102.

Zhang, Q., & Thompson, E. D. (2018). Durability of Iridium Coatings in High-Current Density Environments. Electrochimica Acta, 285, 320-331.

Brown, L. P., & Evans, C. R. (2022). Electrolyte Effects on Anode Performance in Electrowinning Processes. Minerals Engineering, 175, 107-115.

Kim, H. J., & Martinez, F. (2020). Thermal Stability of Coated Titanium Anodes in Aggressive Electrochemical Systems. Journal of Materials Science, 55(14), 5980-5992.

Send Inquiry

Related Industry Knowledge

- Applications of Titanium Anode Baskets

- What is sintered metal fiber felt?

- What is a titanium anode basket used for?

- Choosing the Right Sintered Metal Filter Plate for Your Filtration Needs

- How does a sintered metal filter tube work?

- How Electrolyzed Titanium Sheet Electrode Enhances Electrochemical Processes?

- How do I select the right DSA coating titanium anode for my specific process?

- Understanding the Electrochemical Process Behind Electrolyzed Water Titanium Mesh Electrode

- What Applications Are Suitable for Sintered Metal Powder Filters?

- How Sintered Metal Powder Filter Cartridge Improves Purity and Efficiency?