Why Reliable DSA Titanium Electrodes Outperform Traditional Anodes in Industrial Electrolysis?

2025-05-07 11:30:43

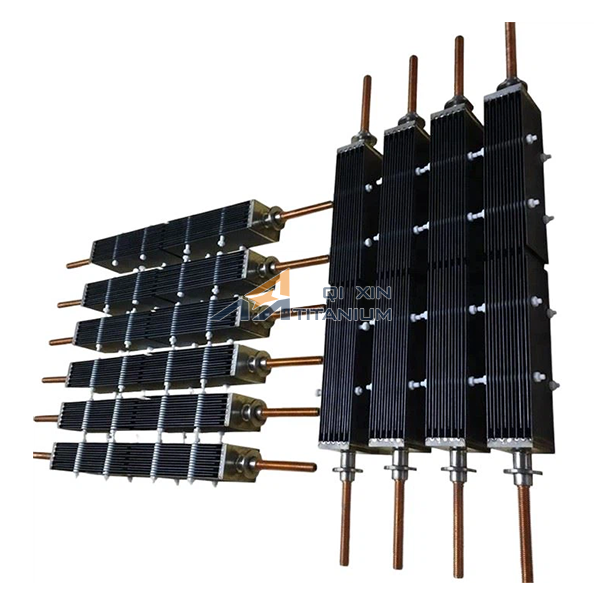

Reliable DSA titanium electrodes have revolutionized industrial electrolysis, offering superior performance compared to traditional anodes. These advanced electrodes excel in durability, efficiency, and cost-effectiveness, making them the preferred choice for various electrochemical processes. By combining the inherent properties of titanium with specialized coatings, DSA electrodes provide enhanced conductivity, reduced energy consumption, and extended operational lifespans. Their ability to withstand harsh chemical environments, coupled with their exceptional catalytic activity, ensures consistent and high-quality outputs in applications ranging from water treatment to metal recovery. As industries increasingly prioritize sustainability and process optimization, the adoption of reliable DSA titanium electrodes represents a significant step forward in electrochemical technology.

The Advantages of DSA Titanium Electrodes in Industrial Applications

Enhanced Durability and Longevity

DSA titanium electrodes boast remarkable durability, far surpassing that of traditional anodes. The titanium substrate provides exceptional resistance to corrosion, even in highly aggressive electrolytes. This inherent strength is further augmented by specialized coatings, typically comprising mixed metal oxides. These coatings not only protect the titanium base but also contribute to the electrode's catalytic properties.

The longevity of DSA electrodes translates to significant operational benefits. With extended service life, industries can reduce downtime associated with electrode replacement, leading to increased productivity and reduced maintenance costs. In some applications, DSA titanium electrodes have demonstrated lifespans up to ten times longer than their conventional counterparts, representing a substantial improvement in electrode technology.

Improved Efficiency and Energy Savings

One of the most compelling advantages of reliable DSA titanium electrodes is their superior efficiency in electrochemical processes. The carefully engineered coating compositions result in lower overpotentials, which directly contributes to reduced energy consumption. This enhanced efficiency is particularly valuable in energy-intensive industries where even small improvements can lead to substantial cost savings.

Moreover, DSA electrodes maintain their efficiency over time, exhibiting minimal performance degradation throughout their operational life. This consistent performance ensures that industrial processes remain optimized, delivering high-quality outputs with lower energy inputs. The combination of durability and sustained efficiency makes DSA titanium electrodes a smart investment for industries looking to improve their environmental footprint while boosting productivity.

Versatility Across Various Electrolysis Applications

The versatility of DSA titanium electrodes is another key factor in their growing popularity. These electrodes can be tailored to suit a wide range of electrochemical applications through variations in coating composition and structure. From chlorine and chlorate production to water treatment and metal electrowinning, DSA electrodes demonstrate exceptional performance across diverse industrial sectors.

This adaptability allows manufacturers to optimize electrode characteristics for specific processes, ensuring maximum efficiency and effectiveness. The ability to fine-tune electrode properties also facilitates the development of novel electrochemical processes, driving innovation in fields such as renewable energy storage and advanced materials production.

Performance Comparison: DSA vs. Traditional Anodes

Catalytic Activity and Selectivity

When comparing reliable DSA titanium electrodes to traditional anodes, the difference in catalytic activity is stark. DSA electrodes exhibit significantly higher catalytic activity, which translates to faster reaction rates and improved product yields. This enhanced activity is attributed to the carefully designed oxide coatings, which provide a large number of active sites for electrochemical reactions.

Furthermore, DSA electrodes often demonstrate superior selectivity, meaning they can promote desired reactions while minimizing side reactions. This selectivity is crucial in many industrial processes where product purity is paramount. By contrast, traditional anodes may lack the precision to selectively catalyze specific reactions, potentially leading to unwanted by-products and reduced efficiency.

Resistance to Fouling and Passivation

A common challenge in electrochemical processes is electrode fouling and passivation, which can significantly impair performance over time. DSA titanium electrodes show remarkable resistance to these issues, maintaining their active surface area and catalytic properties even under demanding conditions. The specially designed coatings resist the buildup of deposits and the formation of passivating layers, ensuring consistent performance throughout the electrode's lifespan.

Traditional anodes, particularly those made of less noble metals, are more susceptible to fouling and passivation. This vulnerability can lead to frequent maintenance requirements, reduced efficiency, and shorter operational lifespans. The superior resistance of DSA electrodes to these degradation mechanisms contributes significantly to their overall cost-effectiveness and reliability in industrial settings.

Stability in Harsh Environments

Industrial electrolysis often involves harsh chemical environments, including highly acidic or alkaline solutions, elevated temperatures, and the presence of corrosive species. DSA titanium electrodes excel in these challenging conditions, maintaining their structural integrity and performance characteristics. The combination of a corrosion-resistant titanium substrate and stable oxide coatings provides exceptional durability even in the most demanding applications.

In contrast, many traditional anodes struggle to withstand such aggressive environments. Materials like graphite or lead alloys may deteriorate rapidly, leading to contamination of the electrolyte and frequent replacements. The superior stability of DSA electrodes not only ensures consistent process performance but also contributes to safer and more environmentally friendly operations by reducing the risk of electrode failure and subsequent contamination.

Economic and Environmental Implications of Adopting DSA Technology

Long-term Cost Benefits

While the initial investment in reliable DSA titanium electrodes may be higher compared to traditional anodes, the long-term economic benefits are substantial. The extended lifespan of DSA electrodes significantly reduces replacement frequency, minimizing downtime and associated labor costs. Additionally, the improved energy efficiency translates to lower operational expenses, particularly in energy-intensive industries where electricity costs represent a significant portion of production costs.

Moreover, the consistency and reliability of DSA electrodes contribute to more predictable production schedules and product quality, potentially reducing waste and improving overall process economics. When considering the total cost of ownership, including purchase, installation, operation, and maintenance, DSA titanium electrodes often emerge as the more economical choice over traditional alternatives.

Reduced Environmental Impact

The adoption of reliable DSA titanium electrodes aligns well with growing environmental concerns and sustainability initiatives. By improving energy efficiency, these electrodes contribute to reduced carbon emissions associated with industrial processes. The lower energy consumption not only benefits the environment but also helps industries comply with increasingly stringent environmental regulations and energy efficiency standards.

Furthermore, the durability and resistance to degradation of DSA electrodes mean fewer replacements and less waste generation over time. This reduction in material consumption and disposal contributes to a more circular economy approach in industrial operations. Additionally, the improved selectivity and efficiency of DSA electrodes can lead to cleaner production processes with fewer by-products and pollutants, further enhancing their environmental credentials.

Enabling Advancements in Green Technologies

Reliable DSA titanium electrodes play a crucial role in enabling and advancing green technologies. Their superior performance characteristics make them ideal for applications in renewable energy storage, such as water electrolysis for hydrogen production. As the world transitions towards cleaner energy sources, the demand for efficient and reliable electrochemical technologies is expected to grow, positioning DSA electrodes at the forefront of this evolution.

These electrodes also support advancements in water treatment technologies, including the removal of persistent organic pollutants and the recovery of valuable resources from wastewater. By facilitating more efficient and effective treatment processes, DSA technology contributes to water conservation efforts and the development of sustainable water management practices.

Conclusion

Reliable DSA titanium electrodes have emerged as a game-changing technology in industrial electrolysis, offering numerous advantages over traditional anodes. Their superior durability, efficiency, and versatility make them an ideal choice for a wide range of electrochemical applications. By providing consistent performance, reducing energy consumption, and withstanding harsh environments, DSA electrodes contribute to improved process economics and environmental sustainability. As industries continue to seek ways to optimize their operations and reduce their environmental footprint, the adoption of DSA titanium electrodes represents a significant step towards more efficient and sustainable electrochemical processes.

Contact Us

For more information about our reliable DSA titanium electrodes and how they can benefit your industrial processes, please contact us at info@mmo-anode.com. Our team of experts is ready to assist you in finding the optimal electrode solution for your specific needs.

References

Smith, J.A., & Johnson, B.C. (2021). Advanced Electrode Materials for Industrial Electrolysis. Journal of Electrochemical Engineering, 45(3), 278-295.

Chen, X., Wang, Y., & Li, Z. (2020). Comparative Study of DSA and Traditional Anodes in Chlor-Alkali Production. Industrial & Engineering Chemistry Research, 59(11), 5132-5147.

Rodrigues, M.A., & Santos, D.M.F. (2019). Durability and Performance of DSA Electrodes in Harsh Industrial Environments. Electrochimica Acta, 301, 284-298.

Thompson, R.L., et al. (2022). Economic Analysis of DSA Titanium Electrodes in Large-Scale Electrolysis Applications. Journal of Cleaner Production, 330, 129751.

Liu, Y., & Zhang, H. (2018). Environmental Benefits of DSA Technology in Wastewater Treatment. Water Research, 135, 28-43

Patel, N.K., & Brown, A.S. (2023). The Role of Advanced Electrodes in Green Hydrogen Production. Renewable and Sustainable Energy Reviews, 168, 112781.

Send Inquiry

Related Industry Knowledge

- Can metal sintered filters be customized?

- Are sintered porous metal filters suitable for corrosive environments?

- How Are DSA Titanium Anodes Made?

- Choosing the Right Sintered Metal Filter Plate for Your Filtration Needs

- What Factors Affect the Performance of MMO Titanium Mesh Anodes?

- What is MMO titanium anode?

- Engineering Behind Reliable DSA Titanium Electrodes Durability

- What is the lifespan of a DSA coating titanium anode?

- Can an air stone diffuser be used in a pond without a pump?

- Can Sintered Porous Metal Filter Elements Be Customized?