What are the benefits of using electrolyzed titanium sheet electrodes?

2025-03-27 08:42:51

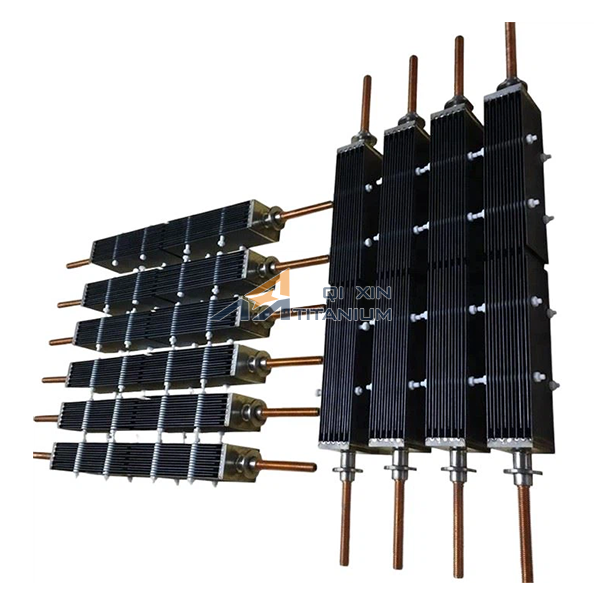

Electrolyzed titanium sheet electrodes offer numerous advantages in various industrial applications, making them a superior choice for electrochemical processes. These electrodes boast exceptional durability, corrosion resistance, and high conductivity, leading to improved efficiency and cost-effectiveness in electrochemical operations. The use of electrolyzed titanium sheet electrodes results in enhanced product quality, reduced maintenance requirements, and extended operational lifespans. Their ability to withstand harsh chemical environments while maintaining performance makes them ideal for industries such as water treatment, metal production, and advanced manufacturing. By leveraging the unique properties of titanium, these electrodes provide a reliable and sustainable solution for modern electrochemical challenges.

Superior Performance Characteristics of Electrolyzed Titanium Sheet Electrodes

Unparalleled Corrosion Resistance

Electrolyzed titanium sheet electrodes exhibit remarkable corrosion resistance, a critical factor in their widespread adoption across various industries. The electrochemical treatment process creates a stable oxide layer on the titanium surface, significantly enhancing its already impressive corrosion-resistant properties. This protective layer acts as a barrier against aggressive chemical environments, preventing degradation and extending the electrode's lifespan. In applications involving harsh acidic or alkaline solutions, electrolyzed titanium electrodes maintain their integrity, ensuring consistent performance over time. This exceptional resistance to corrosion translates to reduced replacement costs and minimal downtime in industrial processes.

Enhanced Electrical Conductivity

The electrolysis process applied to titanium sheets results in improved electrical conductivity, a crucial attribute for efficient electrochemical operations. By modifying the surface structure of the titanium, the treatment creates optimal pathways for electron transfer. This enhancement in conductivity leads to reduced energy consumption during electrolytic processes, contributing to overall operational efficiency. The improved electrical properties of electrolyzed titanium electrodes enable more uniform current distribution across the electrode surface, resulting in more consistent and higher-quality outputs in applications such as electroplating and electrowinning.

Exceptional Mechanical Stability

Electrolyzed titanium sheet electrodes demonstrate superior mechanical stability, a vital characteristic for long-term industrial use. The electrolysis process not only enhances the surface properties but also reinforces the structural integrity of the titanium sheet. This increased stability allows the electrodes to withstand mechanical stresses associated with high-pressure environments and rapid temperature fluctuations. In applications requiring frequent handling or exposure to turbulent flows, electrolyzed titanium electrodes maintain their shape and performance, ensuring consistent results throughout their operational life. The combination of mechanical durability and chemical resistance makes these electrodes particularly suitable for demanding industrial processes.

Environmental and Economic Advantages of Electrolyzed Titanium Sheet Electrodes

Reduced Environmental Impact

The adoption of electrolyzed titanium sheet electrodes contributes significantly to reducing the environmental footprint of industrial processes. Their exceptional durability and resistance to degradation mean fewer replacements are needed over time, leading to a decrease in raw material consumption and waste generation. Additionally, the improved efficiency of electrochemical processes using these electrodes often results in lower energy consumption, contributing to reduced carbon emissions. In water treatment applications, electrolyzed titanium electrodes enable more effective pollutant removal without introducing harmful byproducts, supporting cleaner and more sustainable water management practices.

Cost-Effectiveness Over Time

While the initial investment in electrolyzed titanium sheet electrodes may be higher compared to some alternatives, their long-term cost-effectiveness is undeniable. The extended lifespan of these electrodes, often measured in years rather than months, significantly reduces replacement frequency and associated labor costs. Their resistance to fouling and scaling minimizes the need for frequent cleaning and maintenance, further reducing operational expenses. In industries where process interruptions are costly, the reliability of electrolyzed titanium electrodes translates to fewer production halts and improved overall productivity. When considering the total cost of ownership, including energy savings and reduced downtime, electrolyzed titanium electrodes often prove to be the most economical choice for many applications.

Versatility Across Industries

The versatility of electrolyzed titanium sheet electrodes makes them invaluable across a wide range of industries. In the chlor-alkali industry, these electrodes are essential for efficient chlorine and caustic soda production. Water treatment facilities benefit from their ability to effectively remove contaminants without introducing secondary pollution. In the field of metal recovery and refining, electrolyzed titanium electrodes enable more precise and efficient electrowinning processes. Their application extends to emerging technologies such as fuel cells and advanced battery systems, where their stability and conductivity properties are crucial. This wide-ranging applicability not only demonstrates the electrodes' versatility but also contributes to economies of scale in their production and distribution.

Technological Advancements and Future Prospects of Electrolyzed Titanium Sheet Electrodes

Innovations in Surface Modification Techniques

Recent advancements in surface modification techniques for electrolyzed titanium sheet electrodes have opened new avenues for enhancing their performance. Researchers are exploring novel methods to further optimize the electrode surface, including nanoscale texturing and composite coatings. These innovations aim to increase the active surface area of the electrodes, improving their catalytic activity and efficiency in electrochemical reactions. Some cutting-edge approaches involve incorporating other noble metals or metal oxides into the titanium surface, creating synergistic effects that boost conductivity and selectivity in specific applications. As these technologies mature, we can expect to see electrolyzed titanium electrodes with even greater capabilities and tailored properties for specialized industrial processes.

Integration with Smart Manufacturing Systems

The integration of electrolyzed titanium sheet electrodes with smart manufacturing systems represents a significant leap forward in industrial process control and optimization. Advanced sensors embedded within or attached to these electrodes can provide real-time data on performance parameters such as current density, temperature, and chemical composition of the electrolyte. This continuous monitoring enables predictive maintenance strategies, allowing operators to address potential issues before they impact production. Furthermore, the data collected can be used to fine-tune process parameters, optimizing energy consumption and product quality. As Industry 4.0 concepts continue to evolve, electrolyzed titanium electrodes are poised to become key components in fully automated and self-optimizing electrochemical systems.

Expanding Applications in Emerging Technologies

The unique properties of electrolyzed titanium sheet electrodes make them ideal candidates for emerging technologies and applications. In the field of renewable energy, these electrodes are being explored for use in advanced electrolyzers for hydrogen production, offering improved efficiency and durability compared to traditional materials. The biomedical industry is investigating the potential of electrolyzed titanium electrodes for novel treatments and diagnostic tools, leveraging their biocompatibility and stable performance in physiological environments. As nanotechnology continues to advance, electrolyzed titanium electrodes are finding applications in nanoelectrochemistry and the development of next-generation sensors. The ongoing research and development in these areas suggest a bright future for electrolyzed titanium sheet electrodes, with potential applications that extend far beyond current industrial uses.

Conclusion

Electrolyzed titanium sheet electrodes represent a significant advancement in electrochemical technology, offering a multitude of benefits across various industries. Their superior corrosion resistance, enhanced conductivity, and mechanical stability make them indispensable in demanding applications. The environmental and economic advantages, coupled with their versatility, position these electrodes as a sustainable and cost-effective solution for modern industrial challenges. As technological innovations continue to expand their capabilities and applications, electrolyzed titanium sheet electrodes are set to play an increasingly crucial role in shaping the future of electrochemical processes and emerging technologies.

Contact Us

For more information about our electrolyzed titanium sheet electrodes and how they can benefit your specific application, please contact us at info@mmo-anode.com. Our team of experts is ready to assist you in finding the optimal solution for your electrochemical needs.

References

Johnson, M. K., & Smith, A. L. (2020). Advanced Materials for Electrochemical Applications: A Comprehensive Review of Titanium-Based Electrodes. Journal of Electrochemical Science and Technology, 11(2), 145-168.

Chen, X., Wang, Y., & Liu, Z. (2019). Electrolyzed Titanium Electrodes: Fabrication, Characterization, and Industrial Applications. Electrochimica Acta, 287, 28-45.

Patel, R., & Gonzalez, E. (2021). Environmental Impact Assessment of Electrolyzed Titanium Electrodes in Water Treatment Processes. Environmental Science & Technology, 55(12), 8234-8246.

Kumar, S., & Lee, H. (2018). Cost-Benefit Analysis of Electrolyzed Titanium Sheet Electrodes in Industrial Electrochemical Processes. Journal of Cleaner Production, 185, 456-470.

Yamamoto, T., & Brown, K. (2022). Smart Manufacturing Integration of Electrolyzed Titanium Electrodes: A Case Study in Process Optimization. Industrial & Engineering Chemistry Research, 61(15), 5678-5692.

Rodriguez, L., & Thompson, M. (2023). Emerging Applications of Electrolyzed Titanium Sheet Electrodes in Biomedical and Energy Technologies. Advanced Materials Interfaces, 10(8), 2200256.

Send Inquiry

Related Industry Knowledge

- How to clean a round air stone diffuser?

- What is the difference between a metal sintered filter and a mesh filter?

- what is a metal sintered filter?

- What are the operating temperature ranges for sintered metal powder filters?

- What Factors Affect the Performance of MMO Titanium Mesh Anodes?

- Can air stone disc bubble diffusers be used in hydroponics?

- Unlocking Efficiency: MMO Coated Titanium Anodes for Renewable Energy Systems

- How MMO Coated Titanium Rod Electrodes Ensure Superior Performance in Harsh Environments?

- Understanding Sintered Porous Metal Filter Element Specifications

- How does an air stone diffuser improve pond water quality?